Quick connect grease gun couplers are ideal for applications where there is a need to regularly access multiple sizes and types of grease fittings for lubrication maintenance requirements. Any given machine can potentially have a variety of grease fitting types and sizes that require regular lubrication, so the ability to quickly interchange between couplers to match the fitting size, type, access angle, and location significantly contributes to improvements in overall maintenance efficiencies.

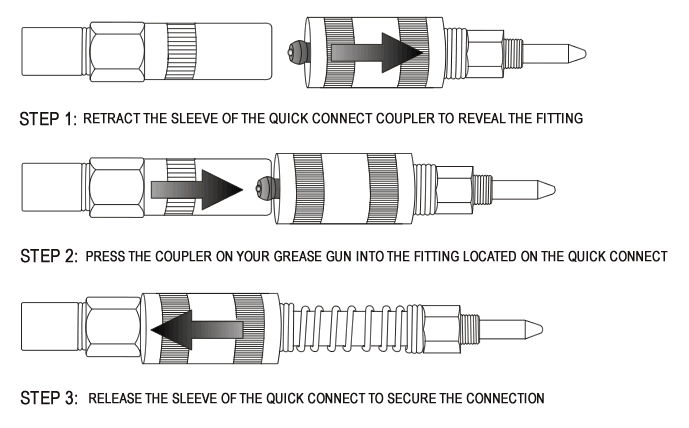

Quick connect grease couplers do not use threads for screw assembly to the grease gun, instead, they simply snap onto any standard coupler to make a leak-proof connection in three easy steps as shown in figure 1.

- Step 1 is to retract the sleeve of the quick connect coupler to reveal the fitting

- Step 2 is to press the coupler on your grease gun into the fitting located on the quick connect coupler

- Step 3 is to release the sleeve of the quick connect to secure the connection between the grease gun and quick connect coupler

Selecting the correct coupling is critical to ensuring a properly lubricated system.

Selecting the correct coupling is critical to ensuring a properly lubricated system.