Your selection of grease fitting couplers is dependent upon the style of grease fitting it will connect to. As discussed in a previous blog post, there are almost as many styles of grease fitting couplers as there are grease fittings. Not to worry….by following the steps below, you will get it right every time!

Selecting the correct coupling is critical to ensuring a properly lubricated system.

Selecting the correct coupling is critical to ensuring a properly lubricated system.

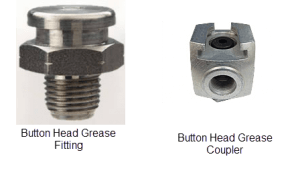

- First, identify the style of the grease fitting you need to connect to.

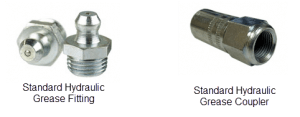

- If it’s a standard fitting then a standard hydraulic coupler will do

- If a button head grease fitting, then you must choose a button head coupler

- Etc.

- Next, confirm that the size of the coupler matches with the size of the grease fitting.

- Last, identify how to access the grease fitting as this can influence the selection of a nozzle vs. a coupler.

- Grease gun hose extensions, right angle couplers, swivels, and adapters may be required to access your grease fitting.

The standard hydraulic coupler is the most commonly used because it fits the standard style grease fitting. Listed below are some of the other types of grease gun couplings you may need and when to use them.

Hydraulic Couplers are designed to grease standard grease fittings.

Hydraulic Couplers are designed to grease standard grease fittings.

- Types include: Narrow, No Check Valve, Heavy Duty, 90-degree Slotted, or Ball-Type

- Lock N Lube Quick Connect Couplers are designed to connect with the grease fitting by pressing a lever to expose and slightly open the jaws of the coupling for a quick connection of easy-to-reach couplings.

- Standard, Giant, and Metric Button Head Couplers fit to button head grease fittings with selection based on size of fitting.

Grease Gun Adapter Kits are a must-have for any lubrication specialist. The tools in this kit allow you to service a variety of fittings with minimal tool change time. Couplers are organized together in a heavy-duty roll up sleeve for easy access and secure storage.

Grease Gun Adapter Kits are a must-have for any lubrication specialist. The tools in this kit allow you to service a variety of fittings with minimal tool change time. Couplers are organized together in a heavy-duty roll up sleeve for easy access and secure storage.- Flush Fitting Couplers/Nozzles are designed to fit flush type grease fittings.

Needle Nozzles are used to lubricate grease fittings in hard-to-reach spaces such as U-joints, CV-joints, or tight spaces.

Needle Nozzles are used to lubricate grease fittings in hard-to-reach spaces such as U-joints, CV-joints, or tight spaces.

- Nozzles are designed to fit into the head of the grease fitting to inject lubricant instead of around the head.

- Because they do not need to match grease fitting head styles, they can lubricate multiple styles of fitting quickly and easily.

- Quick Connect Needle Nozzles and Couplers are a very handy component to have in any lubrication maintenance kit as these quickly snap onto any standard coupler to help access fittings in hard-to-reach spaces.

- Pin Type Couplers work with pin type grease fittings

- Swivel Couplers are another great tool to have handy because they allow you to swivel 180-360 degrees to connect with fittings in reverse positions or need pipe extensions to reach.

SAE Products stocks a complete line of all grease gun couplers listed above and available for online purchase/same day shipping in a variety of sizes to meet your needs. With over 30 years’ experience in the lubrication supply industry, we’re confident we can help you to select the right coupling every time.

Contact Us to buy grease gun couplers and we’ll ship it to you that same day!