When designing equipment that requires lubrication via grease fittings, it is always best to engineer it so the fittings can be accessed easily for ongoing lubrication/maintenance – grease fittings are meant to be greased after all. But not every machine, or the maintenance worker responsible for lubricating the machinery, is designed with lubrication as the top priority. Furthermore, as machinery gets upgrades or customizations over the years, the convenience of easy access to grease fittings is often sacrificed to make room for the enhancement. These are a few of the common reasons explaining the need for the grease fitting accessories shown below. In many instances, grease fitting accessories are the difference between proper lubrication of equipment and no lubrication, which can ultimately lead to mechanical failures.

Grease Fitting Adapters

Grease Fitting Adapters

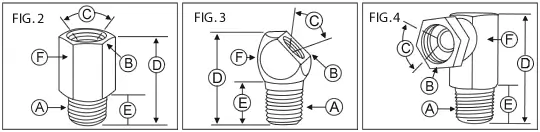

Grease Fitting Extensions are used to extend the area where a fitting is being installed. Simply screw the male end of the extension into the bearing housing or whatever component the fitting is lubricating and attach the fitting to the opposite/female end. Grease fitting extensions can provide over ½ inch extra access, which is often enough to overcome any ‘flush’ mounted components that may be obstructing access to the fitting. Extensions can also be attached to other types of grease fitting adapters to improve access as needed.

Read More