With over 15 different styles to choose from, we are regularly asked, “Which grease gun is the best?”. The answer truly depends on your lubrication applications, pressure requirements, and durability needs, which justifies the diverse variation in grease gun types. The real question to ask is, “Which grease gun is best for me?”. Grease guns are a critical tool for anyone needing to lubricate 1 grease fitting or 1,000+ grease fittings, it’s simply the right tool for the job. The key is to select the right gun so you get the job done right. Get the wrong grease gun and you could find yourself over-spending and/or under-performing.

We decided to put together the information below as a resource to help you make the right decision when selecting the best grease gun to meet your lubrication needs.

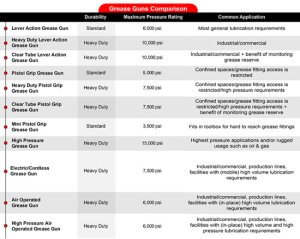

Lever Action Grease Guns are considered the ‘traditional grease gun’ for all intents and purposes. They have a 6,000 psi maximum pressure rating and require two hands to operate. These grease guns are best for most general lubrication requirements.

Lever Action Grease Guns are considered the ‘traditional grease gun’ for all intents and purposes. They have a 6,000 psi maximum pressure rating and require two hands to operate. These grease guns are best for most general lubrication requirements.

- Heavy Duty Lever Action Grease Guns are designed for heavier duty applications where up to 10,000 psi is required. Several other features contribute to their durability including a cast aluminum head, powder coated barrel, and soft rubber grip. The variable stroke lever allows for higher greasing pressures from short strokes or high greasing volume with full strokes. High pressure grease guns are best for industrial/commercial applications.

- Clear Tube Lever Action Grease Guns are essentially heavy-duty lever action with a clear barrel which allows the operator to immediately confirm a grease cartridge is installed as well as monitor the amount of grease remaining in the tube. Clear tube grease guns are best in high use industrial/commercial applications where knowing the volume of grease in the chamber improves efficiencies.

- High Pressure Lever Action Grease Guns develop up to 15,000 PSI and are suitable to dispense grease, sealants, fluids, packings, and highly viscous lubricants. 100% made in the U.S.A. All components are replaceable, which is a unique feature because you can repair this grease gun. They can be used to free up “frozen” fittings or joints and are best for oil and gas applications where the highest pressure is required.

Pistol Grip Grease Guns are designed so only one hand is required to operate them. They feature a heavy duty pull handle with rubber grip and reach a maximum pressure of 5,000 psi. Pistol grip grease guns are best for use in confined spaces where access to grease fittings is restricted.

Pistol Grip Grease Guns are designed so only one hand is required to operate them. They feature a heavy duty pull handle with rubber grip and reach a maximum pressure of 5,000 psi. Pistol grip grease guns are best for use in confined spaces where access to grease fittings is restricted.

- Heavy Duty Pistol Grip Grease Guns incorporates a variable stroke piston and valve arrangement which allows higher greasing pressures from short strokes or high greasing volumes with full strokes. They deliver 1.5 times more grease per stroke than standard pistol grip grease guns with a max. pressure of 7,500 psi. These are best for use in confined spaces where high pressure is needed to access hard to reach grease fittings.

- Clear Tube Pistol Grip Grease Guns allow for immediate recognition of an installed cartridge, or the amount of grease inside the barrel. They feature a variable stroke lever which allows higher greasing pressures (up to 7.500 psi) from short strokes or high greasing volumes with full strokes. Once again, clear tube grease guns are best for professionals working in confined spaces that can benefit from improved efficiencies associated with visual monitoring of grease reserves in the barrel of the gun.

- Mini Pistol Grip Grease Guns fit inside a standard size tool box and are a convenient and economical tool to have on-hand. Featuring a one-hand pistol grip and a unique aluminum die cast head with two discharge ports – the commonly used front port and a top port which can be used in case of clearance issues. Mini pistol grip grease guns are best for hard-to-reach grease fittings and for anyone who needs a reliable grease gun in their toolbox.

Cordless Electric Grease Guns are high quality trigger-operated workhorses that save time and money by combining speed and portability. The 18 Volt motor delivers consistent grease flow at up to 7,500 psi with two rechargeable power packs for unrestricted mobility. These grease guns are absolutely the best option for production line professionals who regularly lubricate grease fittings, but they’re so cool and easy to use that many shops will keep them on-hand as the ‘shop tool’.

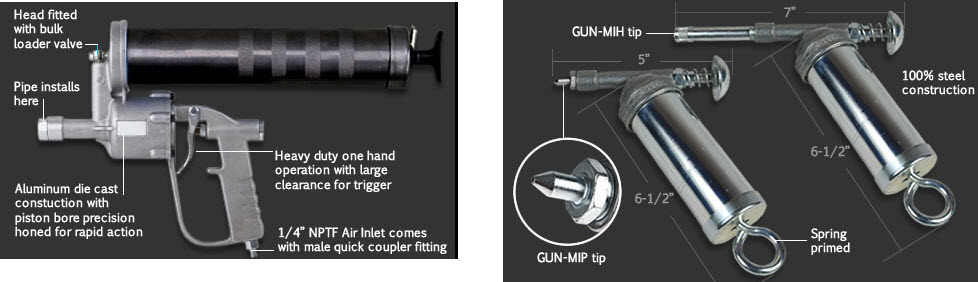

Cordless Electric Grease Guns are high quality trigger-operated workhorses that save time and money by combining speed and portability. The 18 Volt motor delivers consistent grease flow at up to 7,500 psi with two rechargeable power packs for unrestricted mobility. These grease guns are absolutely the best option for production line professionals who regularly lubricate grease fittings, but they’re so cool and easy to use that many shops will keep them on-hand as the ‘shop tool’.- Air Operated Grease Guns connect to an air compressor to provide simple, trouble-free air operation with a trigger mechanism that dispenses grease. Automatic (trigger pull for continuous grease flow) and Intermittent (trigger pull provides a ‘shot’ of grease) versions are available with max. pressure of 6,000 psi. Air operated grease guns are best for professionals who don’t need full mobility, but benefit from quick, comfortable, high repeat usage.

- High Pressure Air Operated Grease Guns are single shot (intermittent) and require a connection to compressed air. These guns produce a 50:1 pressure ratio that generates 1,600 to 6,000 psi discharge pressure. These guns are best for professionals who don’t need full mobility, but benefit from quick, comfortable, high repeat usage with high pressure requirements.

- Mini Grease Guns deliver pinpoint accuracy and feature a palm and finger-grip design that allows easy one hand operation. Pointed tips are available for flush fittings and hydraulic tips are available for standard nipple fittings. Made in America from 100% steel construction. Mini air operated grease guns are best for lubricating chainsaw bar tips, bicycles, and other applications in confined areas where standard grease guns cannot be used.

- Push Type Grease Guns are compact and portable, best for quickly greasing lawn mowers, chain saws, ATV’s, autos, pallet trucks, boats, jet skis, etc. Available with a hydraulic nozzle suitable for ball-type and hydraulic-type nipples or a pointed nozzle suitable for flush-type nipples.

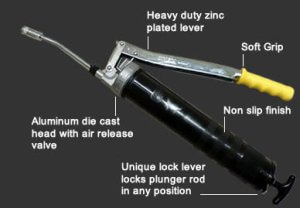

- Lever Action Oil Guns are designed with sealing elements that allow leak proof operation making them the best choice for oils and high-viscosity grease. Oil guns feature a shock and rust-resistant polyamide barrel, air release valve, and aluminum die cast head.

Push Type Oil Guns are smaller, ‘toolbox’ size and designed with sealing elements that allow leak proof operation making them best for oils and high-viscosity grease. Features include zinc plated steel nozzles with protective covers and a telescopic tube suitable for precise lubrication. Available with a hydraulic nozzle for ball-type and hydraulic-type nipples or a pointed nozzle for flush-type nipples.

Push Type Oil Guns are smaller, ‘toolbox’ size and designed with sealing elements that allow leak proof operation making them best for oils and high-viscosity grease. Features include zinc plated steel nozzles with protective covers and a telescopic tube suitable for precise lubrication. Available with a hydraulic nozzle for ball-type and hydraulic-type nipples or a pointed nozzle for flush-type nipples.- Oil/Fluid Suction Guns are best for draining and filling non-corrosive liquids and oils in gear cases, transmissions, and other applications. Features include a premium powder coated steel barrel, deluxe lip seal for maximum suction, and 12 inch flexible vinyl hose.

- Transfer Guns draw in and pump out liquid in a single stroke. Suction head & piston have an aluminum construction and use Viton piston rings. Best for siphoning fuel oils, mineral oils, synthetic oils, petrol, cooling liquids, water, antifreeze, brake fluids, and more.

Contact Us for the best grease guns at the best prices.

1-800-588-8480